Department of Food Process Engineering

Food process engineering is a multidisciplinary field which combines and applies principles of science and engineering to food. Food process engineers provide the technological knowledge transfer essential to the cost-effective production and commercialization of food products and services.

In the College of Food Science and Technology, Pulivendula, the Department of Food Process Engineering offers 10 Courses to the Under Graduate Students of B.Tech. (Food Tech.). The syllabus is as per the recommendations of VI Deans committee of Indian Council of Agriclture Research (ICAR). The courses are as follows.

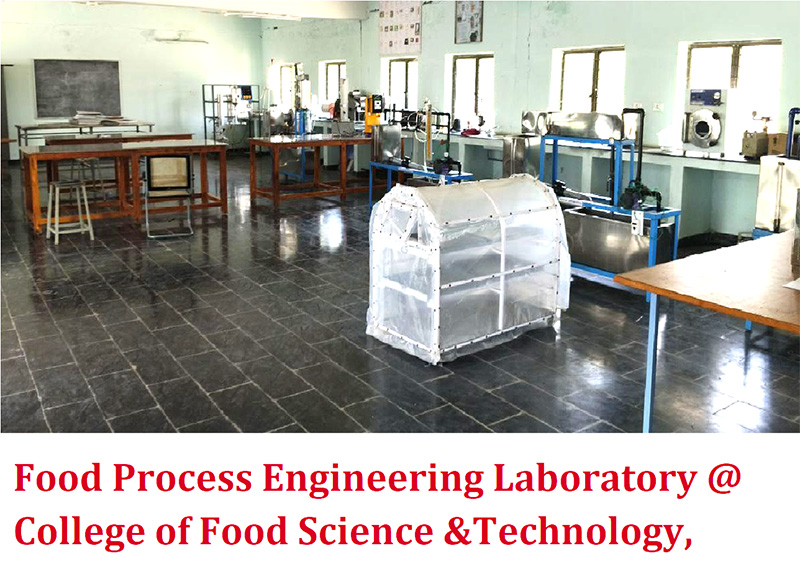

The lab is designed to ergonomically use food processing equipment and spread floor space of 1800 sq. Ft. (60× 30 ft). It accommodates advanced equipment and committed to give hands on training to students in learning of basic unit operations and instrumentation techniques. Food Process Engineering department is actively updating the equipment and other resources required to strengthen the lab facilities.

Courses Covered

- Workshop Technology

- Engineering Drawing and Graphics

- Basic Electrical Engineering

- Food Thermodynamics

- Post-Harvest Engineering

- Fluid Mechanics

- Heat and Mass Transfer in Food Processing

- Basic Electronic Engineering

- Unit Operations in Food Processing

- Fundamentals of Food Engineering

- Food Refrigeration and Cold Chain

- Food Storage Engineering

- Food Process Equipment Design

- Instrumentation and Process Control in Food Industry

Important instrument/equipment

- Texture analyzer part no. CT3-50K (Brookfields)

- Multi-volume pycnometer 1305

- Electronic Moisture balance

- Rice sheller

- Colorflex 45/0 spectrophotometer (Hunter Colour Lab)

- Clarity High-Resolution Digital Visualiser Model PH-8000M

- 8 channel temperature-logger with software

- Surface roughness tester time model TR-200

- Precivas vacuum pump double stage-Direct drive

- Vacuum ovens digital

- Muffle furnaces with temperature control-cum- indication by microprocessor-based PID

- Coefficient of friction test apparatus

- Thin layer drier -lab model

- Solar tunnel dryer

- Temperature transducer trainer

- LVDT trainer

- Water level control by PLC

- Pressure transducer trainer

- Water level measurement trainer

- Fatek PLC trainer

- Dielectric constant

- Notch Apparatus

- Reynolds Apparatus

- Venturi meter and Orifice meter

- Rotameter Calibration Apparatus

- Vapour Compression Refrigeration System tutor

- Tensile Strength Tester

- Ball mill

- Freeze drying system with the bulk rack assembly

- Lab Willey Grinder

- Sieve Shaker (Gyratory Model)